1989

THE Origins

Eurofeedback was founded by Jean-Yves MARTIN, power electronics engineer, at the age of 37.

At that time, power electronics made strong progress and began to become a profession for specialists. Faced with this observation, large companies are refocusing their design offices on their core business and are turning to subcontracting for these specialized trades. Eurofeedback is born from the opportunity offered by this change in the market and will become this specialist.

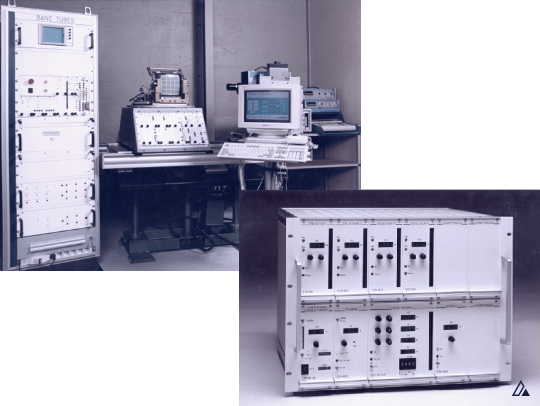

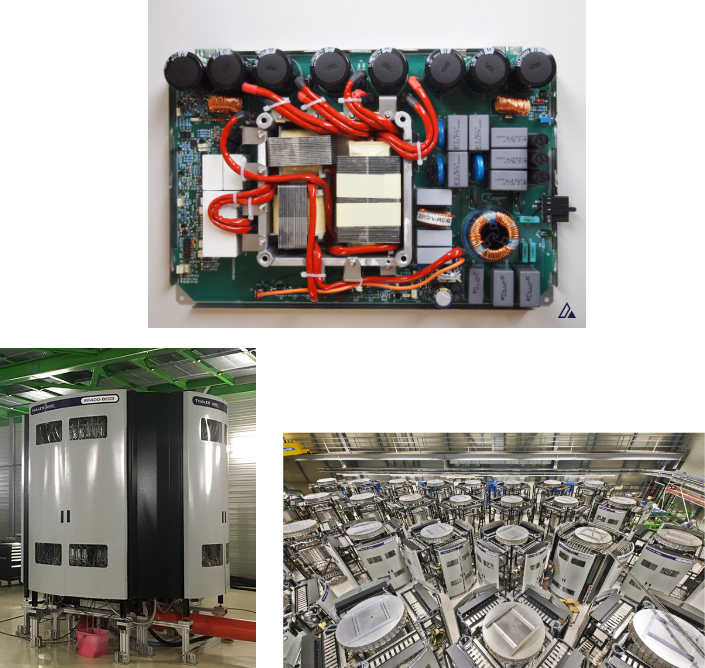

As in the best entrepreneurial stories, Jean-Yves, with his seventeen years of experience in the field and passionate about his profession, begins in a small cellar of a building with an office area and a laboratory area. He works day and night for his first client: Thalès. Eurofeedback designs and manufactures ATOP traveling wave tube power supplies for it.

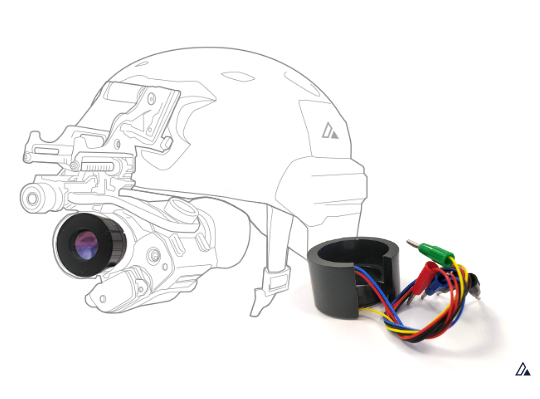

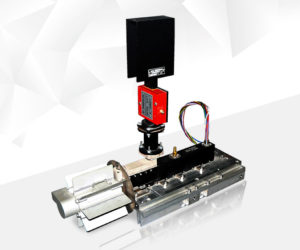

The company will evolve, grow, undergo transformations and diversifications, but this initial DNA will guide all these evolutions and continues today: innovation and expertise in power electronics and optics at the service piloting tubes (or flash lamps). And this, with a level of robustness and reliability well beyond consumer standards, in the space and military fields.

A know-how around light refined during more than 30 years of adventures in the industrial, space and military markets for renowned companies such as General Electrics, Thalès, Philips, Alcatel, and around which will be designed and manufactured power supplies or test benches for in particular:

- cathode ray tubes for television screens,

- cathode ray screens in airplane cockpits,

- X-ray tubes for scanners,

- radiotherapy tubes,

- night vision tubes,

- Xenon tubes for very high speed printers.

Traveling wave tube